Cornell Forge is an industry-leading manufacturer of precision forged components. Since 1930, our family-owned company has been committed to providing unsurpassed quality and customer service. By combining heritage craftsmanship with advanced modern technologies, we deliver accuracy, efficiency, and reliability in everything we do.

Our Chicago-based location offers convenient access to an industrial network that facilitates prompt customer service and delivery to clients across industries, including agriculture, construction, defense, and mining.

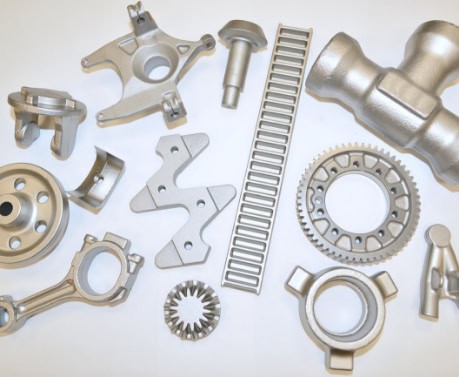

At Cornell Forge, we have proven expertise in forging a diverse range of products and highly complex parts (all of which are made in the USA), specializing in the following capabilities:

- Net forging

- Micro-alloy forging

- Precision-engineered components

As a best-in-class American forging company, we offer flexible order quantities and value-added services that streamline production to optimize results for our valued customers. Read on to learn more about the benefits of partnering with us and the industries we serve.

Key Benefits of Choosing Cornell Forge for Your Next Project

1. Enhanced Micro-Alloy Capabilities

With our vast experience in micro-alloy forging, our team has the resources, capabilities, and expertise to produce top-quality components with outstanding fatigue resistance, durability, and strength.

Micro-alloys deliver exceptional performance and do not require heat treatments, resulting in enhanced part reliability and cost savings. Micro-alloyed parts perform well in high-stress environments and are best suited for construction, defense, and off-road equipment industries.

Micro-alloy forging provides:

- Significant cost savings by eliminating the need for post-process treatments

- Enhanced mechanical properties

- Extended service life for critical components

2. Bar Stock vs. Forging: Why Forging is Superior

Forging optimizes material grain flow, a significant advantage compared to machining bar stock. The forging process minimizes defects such as stress fractures and porosity and eliminates weak points.

Forging typically requires less machining than bar stock and has a lower material cost due to the near-net shape produced. While bar stock machining shapes components by removing material, forging uses pressure to form precise metal shapes, effectively aligning the grain structure with the end part design.

When comparing machining bar stock vs. forging, the forging process is superior in terms of the following advantages:

- Better fatigue and impact resistance

- Improved longevity, especially in demanding environments

- Minimized secondary operations, lowering costs and production time

The aerospace, automotive, and industrial equipment industries, in particular, rely on forged components over machined counterparts for enhanced durability and strength.

3. Flexible Order Quantities for Every Project

At Cornell Forge, we support small- and large-scale production to meet the specific needs of our clients. Our versatile operations can accommodate orders of varying sizes, from a prototype run to high-volume manufacturing, and our customized delivery schedules are flexible to help customers manage inventory and stay on track.

This versatility allows us to serve critical industries, such as:

- Military & defense

- Oil & gas

- Mining

- Railroads

- Off highway

- Truck components

- Construction

- Agriculture

- Forestry

- Marine

- Recreational

- Gear box

- Hand tools

4. Net and Near-Net Forging Expertise

Our net and near-net forging solutions produce components close to their final shape, minimizing the need for additional machining services. Near-net forging offers:

- Lower production costs

- Minimal material waste

- Reduction in delivery lead times

With near-zero draft angles, precision forging from Cornell Forge guarantees each part meets your specific design requirements, eliminating additional processing steps. Switching from bar stock or casting to net forging gives our customers stronger, more reliable components and considerable cost savings.

5. Value-Added Services to Streamline Production

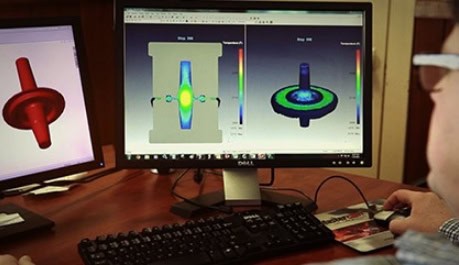

Cornell Forge offers custom manufacturing and various value-added services to reduce production delays and enhance product quality. The following services help our customers streamline their processes:

- Assembly

- In-house tooling design

- Plating, painting, and heat treatment

- In-house Magnaflux inspection (non-destructive testing)

- Precision machining

We also offer design consultations through our experienced engineering department and on-site metallurgist to optimize product cost and performance. Our concurrent engineering process ensures every project runs efficiently from beginning to end, providing our customers with unsurpassed product quality.

6. Decades of Family-Owned Craftsmanship

Cornell Forge has been a family-owned business since 1930, building a legacy of innovation, reliability, and craftsmanship. Our multi-generational experience allows us to provide personalized solutions to meet the unique demands of various industries, including agriculture, construction, and defense.

We take pride in our customer-centric approach, building long-lasting partnerships by anticipating our clients’ needs with continuous innovation. Every component is crafted with expertise, care, and an unwavering commitment to excellence.

7. Made in the USA: Strength in Domestic Manufacturing

Cornell Forge supports domestic manufacturing standards by producing all forgings in the U.S. We focus on responsive customer service and transparent communication so that every order meets or exceeds expectations.

Our Chicago-based facility works closely with the following local suppliers:

- Heat-treating facilities

- Machining facilities

- Testing facilities

With close proximity to main transportation routes and Midway Airport, we can provide fast, reliable delivery to customers throughout the country.

Industries We Serve With Precision Forging

The industries served by Cornell Forge benefit from the following high-performance forged parts and components:

Agriculture

Durable parts for off-highway equipment and heavy-duty machinery

Defense and Military

Reliable parts and components for mission-critical defense operations

Construction and Mining

Forged parts designed to withstand extreme environments

Oil and Gas

High-strength components for infrastructure, drilling, and pipelines

Our forged components are tailored to meet the specific needs of our customers and can perform in harsh conditions, ensuring long-term performance and reliability.

Why Choose Cornell Forge?

Cornell Forge offers a unique combination of craftsmanship, experience, and innovation. Our advanced forging processes produce quality components with superior reliability and strength, enhancing product performance and reducing material waste.

The following capabilities allow us to meet the diverse needs of many industries:

- Expertise in micro-alloy and net forging

- Flexible order quantities

- Value-added services

Cornell Forge works closely with customers to offer reliable delivery, cost-efficiency, and personalized customer service, regardless of whether you need a small custom run or high-volume production.

READY TO ELEVATE YOUR FORGING SOLUTIONS WITH CORNELL FORGE?

Companies that work with Cornell Forge benefit from almost a century of experience in advanced metallurgy and precision forging. Our Made-in-the-USA forging company supports domestic manufacturing and supplies near-net forged components, value-added services, and micro-alloy expertise.

Request a quote today to learn more about how our capabilities can serve your next project.